In the world of shipping and storage, protective packaging materials play a crucial role in ensuring the safety of goods during transit. Among the various options available, Expanded Polystyrene (EPS) and Expanded Polyethylene (EPE) foam are two commonly used materials. In this blog, we’ll delve into the characteristics of both foam, highlighting their differences and helping you make an informed decision when choosing the right packaging material for your needs.

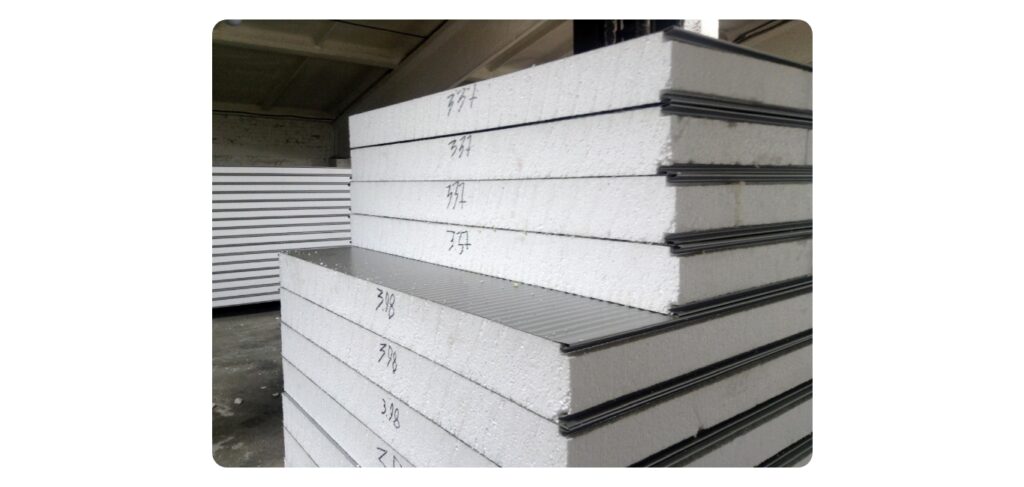

What is EPS Foam?

EPS foam, also known as Styrofoam, is a lightweight and rigid material widely used in packaging and insulation. Manufacturers expand polystyrene beads and mold them into various shapes and sizes to create EPS foam. This foam is prized for its excellent shock-absorbing properties, making it ideal for protecting fragile items during shipping and handling. Additionally, it offers good moisture resistance and provides effective thermal insulation.

What is EPE Foam?

EPE foam, or Expanded Polyethylene foam, differs from EPS foam in its softer and more flexible nature. Created by expanding polyethylene resin, EPE foam features a closed-cell structure that contributes to its durability and resilience. EPE foam is commonly used in packaging, cushioning, and insulation applications where flexibility and impact resistance are paramount. Furthermore, it is resistant to chemicals and moisture, making it suitable for a variety of environments.

Key Differences between EPS and EPE Foam

- Flexibility: EPE foam is softer and more pliable than EPS foam, allowing it to conform to irregular shapes and provide better cushioning for delicate items.

- Shock Absorption: While both foam offer good shock absorption, EPS foam tends to be stiffer and provides superior protection against high-impact forces.

- Water Resistance: EPS foam exhibits better moisture resistance compared to EPE foam, making it suitable for outdoor applications or packaging items that may be exposed to moisture.

- Thermal Insulation: EPS foam offers better thermal insulation properties than EPE foam, making it ideal for applications where temperature control is important.

- Cost: EPS foam is generally more affordable than EPE foam, making it a cost-effective option for certain packaging needs.

Comparison Table: EPS vs. EPE Foam

| Property | EPS Foam | EPE Foam |

| Flexibility | Rigid | Soft and Flexible |

| Shock Absorption | Good | Good |

| Water Resistance | Better | Moderate |

| Thermal Insulation | Good | Moderate |

| Cost | Lower | Higher |

Considerations for Choosing Between EPS and EPE Foam:

- Type of Items Being Packaged: Consider the fragility and shape of the items to be packaged.

- Shipping and Handling Conditions: Evaluate the potential for impact and moisture exposure during transit.

- Environmental Impact: Take into account the recyclability and sustainability of the foam material.

- Cost Considerations: Balance the benefits of each foam type with your budget constraints.

Conclusion

In conclusion, choosing between EPS and EPE foam depends on your specific packaging needs. At BlueRose Packaging, we offer both options to ensure your items are protected during transit and storage. With our commitment to quality and customer satisfaction, you can trust BlueRose Packaging to provide reliable packaging solutions tailored to your requirements. Choose BlueRose Packaging for peace of mind and superior protection for your valuable goods.